Është e nevojshme për rruget ose zonat e parkimit të jenë sigurt dhe organizuara, çka mund të ndodh vetëm kur shenjat në asfalt janë larg dhe përkrahur nga mbajtja rregullore. Por këto shenja mund të bëhen vjetër me kohë apo duhet të hiqen në raste të caktuara. Nese jeni thjesht punonjës i përgjakur për këtë detyrë, nese e keni pronën dhe doni të përmirësoni vendin tuaj apo nëse jeni Planifikator Qytetar që po kërkon të përmirësojë lëngimin e trafikut - të jeni i njohur në mënyrën siç duhet të hiqen shenjat në asfalt efikashtë mund të ruaje jetë personash. Kjo gids do të hape një rang të metodave, mjete dhe konsele ekspert në mënyrën për të hiqur shenjat në asfalt më efikashtë dhe me kushtet më larg.

Përveç seka janë shumë metodë të ndryshme për të larguar shenjat e pavimentit, secila prej tyre vjen me përfitimet dhe aftërshmëri të saj. Larg, janë disa teknika më përdorura:

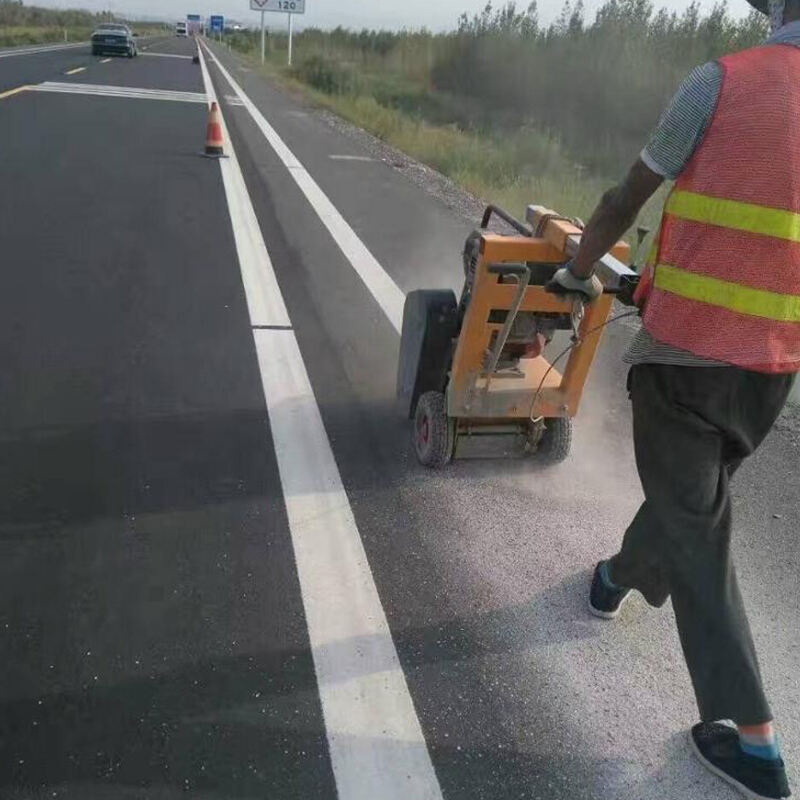

Largimi me gjer: Një zgjidhje efikase, ku pajisjet me diamant largojnë shenjat nga beton ose asfalt. Kjo metode është e përshtatshme për të larguar ato shenja të vështira dhe të thelluara në pavimentin e rradhit, duke lejuar largimin e tyre me precizion dhe me dëmthnie sipërfaqe minimale. Por mos e keni gabim, largimi me gjer mund të jetë i lag i dhe larg dhe proces i therrë (duhet të kenëpërdorni ekipimet e sigurisë standarde për këtë).

Blastimi me ujë: Një përgjigje tjeter përfshin përdorimin e ujit në presje larg për të larguar shenjat nga sipërfaqet e pavimenti në mënyrë e ndali. Blastimi me ujë nuk është sa abraziv dhe nuk shkakton dëmthmie shtesë në paviment siç bën largimi me gjer, dhe gjithashtu mund të largojë shenjat shumë vizible në sipërfaqe. Përmes kësaj, me këtë metodë ekologjike, epari nuk është edhe problem. Megjithatë, disa shenja që kanë qenë të gravuara në paviment për një kohe të gjatë janë paqas falas dhe do të largojnë pavimenti të ulur, duhet kohë e mjaftueshme për të ushqyer para se të riaplikohen të reja.

Largimi Kimik: Si një alternativë, largimi kimik i cili përdor kjime të veçanta për të zgjedhur ose ndarje shenjave në një pikë të caktuar, për të qenë e lehtë të largohen apo të shpërthehen. Kjo është një mjet shumë efektiv për të eleminuar të gjitha llojet e shenjave pa të bëjë zë ose gjerë. Por sigurohuni të e përdorni me kujdes, sepse aplikimi pa rregull kanë aftër të largojnë ose të ndryshojnë ngjyrën e pavimentit tuaj.

Bllokim me Lodh: Këtu është metoda e fundit ku përdoren lodhte çelqe për të bllokuar shenjat nga sipërfaqja. Kjo metode është e mira për të larguar shpejt dhe e lehtë shenjat e theksuara. Vetëm jini vjen në dëmtim të një aspekti kryesor- bllokim me lodh mund të bëhet i lagjter, me gjerë dhe do të hidhë fragmente rreth, për të cilin duhet të punoni afërish ose në një menyre që do të ndikojë në rrjedhjen e lëndes për shembull.

Praktikat që duhet të shpërngulni ndërkohë që largoni sistemet e sigurisë së transportit -- Është e rëndësishme për ju si përbashkëtari dhe agjencija e transportit të biznesit tuaj nëse ka gabime që shpesh duketen këmbyesa, ose mund të shkojnë në fshirje pjesëruese / ose dëmtim që do të sjellë koste shtesë. Largimi i këtyre gabimeve kryesore duhet të jetë i shmangur.

Një nga elementet e themelit në këtë është nevoja për të priorizuar sigurinë, në mënyrë që largimi i varfave të mos bëjë një rrezik për punonjësit apo vodhërët. Nga përdorimi i ekipimenteve personale të mbrojtjes, deri në vendosjen e kontrollit të trafikut në zonën e punës dhe dukeu bërë vlerësigur protokolat tonë të sigurisë.

Identifikimi i Shenjave: Pra, duhet të sigurojmë se lloji i shenjës që po largohet, p.sh. - ngjyrë apo termoplastik nga Lenta, identifikohet saktësisht për t'u shpëngur çdo konfuzion dhe rrezik për siguri. Metoda e drejte për largimin e shenjës duhet të zgjidhet sipas arritjes së saj, përgjatë apo jo.

Siguro ni që Siperfaqja është Përgatitur: Sigurohuni që para se të zgjidhni këtë metodë, keni larguar dhe shpuar siperfaqen për të larguar çdo lodhje nënshkruese si edhe lule ose fragmente. Kjo përgatit sipërfaqen për marjen e re që do të ngjitet dhe mban larg e dëshmuar siperfaqeve gjatë largimit.

Metod Sistematik: Largimi i shpejtë mund të thjeshtojë, jo largim total dhe kaq dhe të arrijë dëmtim në rrugë. Një-jetë e vetme për të siguruar se largimi është efikas dhe i sigurt është duke planifikuar punën deri në hollë detaje, duke zgjedhur mjete dhe teknika të përshtatshme për të larguar sigillantë ose mbushje me efikasie pa vendosur ndonjë person në rrezik të ekspozimit ose të ndaluar funghi të fshehtuara gjatë pastrojes.

Shenjimet e pavementit largohen tipikisht në një proces i thelluar dhe i kohëzor, i cili kërkon ekipamente specifike. Pra, këtu janë disa nga mjerrat e reja që mund ta bëjnë atë dhe me shpejtësi dhe efikasie paguajmë shenjimin.

Mikserë me Larg dhe Larg - Kjo lloj është më eja, duke përdorur rreshta laser për të ushtruar lartat që largojnë shenjat me afër të vogel për dëmtim sipërfaqe. Mikserë me ushtrime laser janë ideale në krahasim me konkurrentët e tyre sepse përdorin sisteme vacuum për të rritur gruajtjen e thellave dhe larg dhe larg ndërlargimin e shenjave asfalti më sigurt.

Kamionet e Blasterit me Ujë - Këto kamione janë projektuar specifik për të punuar me pajisje blasteri me ujë në presje larg dhe sistemet e tyre vakuum që na lejon të hyjmë dhe dalim lehtësisht nga puna kur shenja jepet larg. Kamionet e blasterit me ujë punojnë veçanërisht mirë në shenjat e gjerë të autobleve dhe janë një opsion i sigurt për mjedisen.

Produkte për Largimin e Kimikave - Ka një numër produkte kimike që do të zgjatën ose të largohen shenjat e asfaltit, kështu që mund të largohen thjesht, ose të shpallet në presje. Sigurohuni të zgjidhni produktet ekologjike dhe të lehtë për aplikim për rezultate më të mira.

Nëse jeni një kontratant me shpërfille, ose një i posedhur i larg dhe energik i përbërjeve - vijmë dhe këto rekomandime profesionale për heqjen e siguruar dhe efikase të shenjave në pavimentin është e nevojshme. Disa këshilla mira që vlen të ndjekni gjatë kësaj procedurës:

Ekipi Sigur: Largoni të gjithë punonjësit të jenë gati me rradhat e sigurisë të Mir alert, illogarit për mbrojtje të syve vetëm; dëganojnë ndihmë për të ndihmuar në fusha të zvogëllosha dhe duhet të jetë edhe ekip i mbrojtjes respiratorike nëse mjedisi ka kërkuar atë. Të gjitha pjesët e bashkuara në procesin e heqjes duhet të jenë formuar sipas regullave të sigurisë dhe ekipit.

Zgjedhja e Teknikës dhe Ekipit: Përdorimi i metode të drejte për heqjen e shenjave në paviment dhe zgjedhja e instrumenteve të përshtatshme është e parë. Më e mira është të pyesni këshillën nga inxhinierë të eksperimeve dhe prodhuesit që mund të identifikojnë opsionet e duhura për nevojat tuaja.

Mbroji trotuara përlargje: Vendos plyuvud në trotuarin e rrethueshëm nëse procesi i largimit mund të e zënë ato. Kjo bën për të siguruar se praktika e largimit nuk e dëmtjon sipërfaqet tjera që janë në afërime.

Zgjerimi i një zgjidhje larg kushteve për largimin e shenjave në trotuar

Kjo është hera e tretë vetëm në Colorado këtaj vit në të cilën ka ndodhur një operacion i plotë i rregullimit të rradhës së rrotullave. Pajisja, nevojitet dhe kushte ekonomike të cilat mund të ndihmojnë industritë për të ruajtur parash të drejtat dhe për të menaxhuar pajisjen e tyre:

Ekszekutimi Strategjik: Largimi duhet të planifikohet para me mjete kontrolli të trafikut, kushte atmosferike dhe kërkesa sigurie për të shmangur koste të ardhshme të rritura.

Zgjidh metodën dhe mjetet e duhura: Përdorimi i një metodologie të përshtatshme përfshirë me ekipim të përshtatshëm mund të ndihmojë të minimojmë kërkesat e burimeve, duke larguar kushtet e largimit të asbestit.

Largimi i ndihmës së Profesionistëve: Punimi me një industrje të largimit të shenjave në asfalt, ku ju lidheni me kontratantë/krijuar dhe bashkëpunonit, mund të jetë shumë i dobishëm. Këto ka njohuri të drejta, dhe ata kanë edhe ekipamente të tillë përmes të cilëve largimi i efektiv i vlerave mund të ndodhë.

Për përgjithmint, largimi i shenjave në asfalt është një aspekt i rëndësishëm për të siguruar lëng prej rrezikut dhe organizim të mirë të rrjedhjes së trafikut në lloje të ndryshme pavimentash. Kontratantët, si dhe tëziejt e pronës dhe planifikatorët qytetarë mund të kryejnë largimin kohor të shenjave ekzistues në asfalt duke përdorur praktikat më të mira të disponueshme në industri, duke përdorur teknika dhe mjete më të reja, të cilat janë larg dhe afërte për të arritur një proces të eficient për largimin e shenjave në rrugë, e cila bën për të krijuar një ambient të sigurt në rrugat tona.

Largoni larg profitin nga përvoja e një largimi të shenjave të pavementit me mbi dy dhjetor përvoje në industrinë. Ne jemi në treg për të gjashtë dhe e dimë detajet e teknologjisë që përdoret për të shenjuar rrugat.

Largimi i 10000m2 i instalisë tonë është fabrika e mëdha e prodhimit të mashinave për shenjim të rrugës në Kinë. Ajo ofron ndryshe artikuj për të plotësuar nevojat tuaja për shenjim të rrugës. Me fokus kryesor në largimin e shenjave të pavementit, ne sigurojmë kohë të shpejtë për dërgim, që do të ju sigurojë që produktet tuaja të arrijnë në kohë dhe pa vitime.

Ekipa jonë profesionale në inxhinieri ka qenë vesh e përcaktuara për ofrime të plotë të largimit të shenjave të pavimentit dhe inxhinieria e shenjave të rradhës. Ofrojmë zgjidhje të personalizuara bazuar në eksperthimin e tyre në industrinë për të kryer nevojat dhe probleme tënde. sigurojmë performancë optimale dhe efikasni për projektin tënd të shenjave të rradhës.

Shërbimi jonë pas shitjes është i plotë dhe ofron larg dhe qetësi. Ne ofrojmë garanci gratis për një vit për të gjitha larmjet e shenjave të pavimentit. Kaq edhe eshte mbuluar nga një lanc total i furnizimeve që përfshin pjesë pastrim të pavimentit të ndjeshme nga brendit e rregulluara në nivel mondial, specifikisht dizajnuar për mashinat e shenjimit të rradhës në industrie. Ne jemi veta e angazhuar për performancën dhe gjatësinë e pajisjeve tënde.